Simulation Data Management – SDM

contact usWhat is Simulation Data Management?

Our definition of Simulation Data Management

The need to develop increasingly mechatronic and cyber-physical products or systems confronts companies in all sectors with new interdisciplinary challenges. There is a need to describe the physical products completely digitally and to be able to simulate all functions in advance (Digital Twin, Digital Prototype, Digital Master). This cannot be done without efficient data management of the underlying digital models. Simulation data management systems (SDM systems) specialize in meeting precisely these requirements and thus establishing a continuous and (as far as possible) automated process chain from model construction to simulation to reporting of the results. But SDM is more:

“SDM includes all methods, processes and tools that are important for simulation and calculation, as well as the activities and interfaces that are necessary to integrate CAE into the entire product development process.”

Companies are thus faced with the challenge of managing the accumulating data volumes in a structured, secure and comprehensible manner (for customers and audits) and defining a corresponding IT solution concept. In the future, aspects of data integration, data networking and data management for individual product instances will also have to be taken into account in the context of digitalization. This also requires, for example, close interaction between test data management (TDM) and SDM. Systems Engineering Data Management (SE-DM) is therefore necessary across the entire V-Model.

What added value do our consulting services in Simulation Data Management offer you?

System-independent consulting for the conception, selection and introduction of simulation data management solutions

Support in the implementation of the necessary organizational measures in the simulation area (simulation processes and simulation governance)

Holistic view of model-based product development in the context of the integration of test data management and systems engineering

Simulation Data Management – our consulting services

There are a large number of IT applications for simulation data management on the market that have been developed by CAE and PDM providers or specifically as a data platform for CAE data. Companies have to find the right solution depending on the existing framework conditions from the CAE process point of view, but also from the point of view of the corporate strategy and the existing IT structure. We support you as an independent consultant with more than 20 years of experience in the implementation of a simulation data management with special consideration of the future challenges of Systems Engineering.

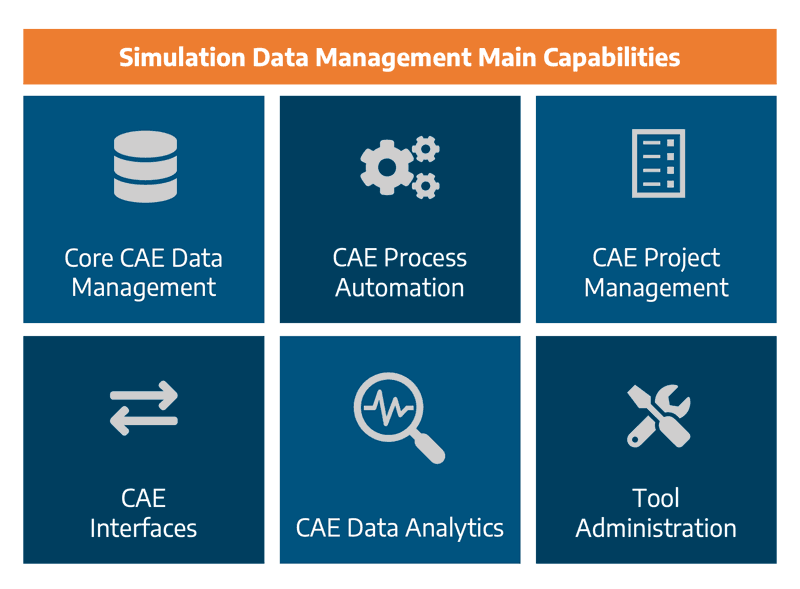

In doing so, we take a close look at the necessary core functions that are required for a successful SDM implementation in your company and evaluate them together according to the requirements of our customers within the framework of specific use cases.

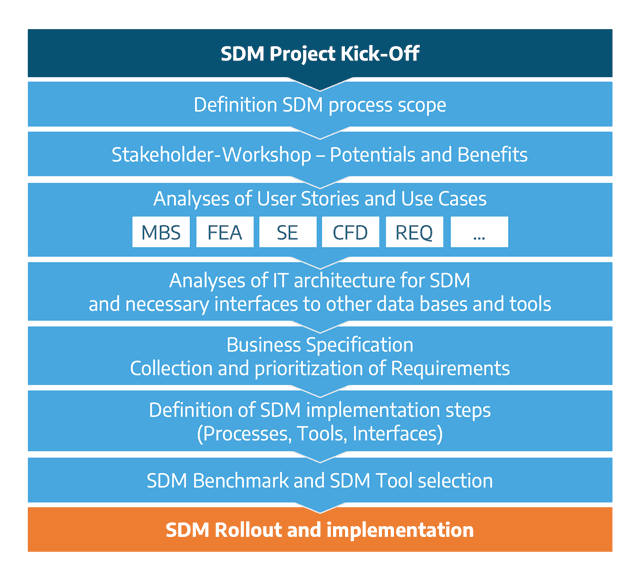

Efficient introduction of SDM systems – Our procedure model

1. Needs and potentials

- Create awareness for SDM at management and departmental level

- Analysis of the needs and possible potentials for SDM

- Analysis of the existing IT structure and interfaces for the SDM

- Use cases analysis of existing CAE data flows and information

- Development of a business case with profitability analysis and cost-benefit analysis

2. Concept and specification and system selection

- Preparation of a concept study and a specification sheet for the implementation

- Development of a company-specific data model based on existing reference data models

- Development of a strategy and concept for an IT construction

- Documentation of the requirements within the framework of a specification for the provider

- Advice on system selection within the framework of benchmarks and PoCs (proof of concepts)

3. Implementation, introduction and operational support

- Conception and support of the SDM rollout project

- Supervision of pilot projects with users

- Definition of MVPs (minimum viable products) for the agile implementation of SDM

- Project management

- Introduction and test of the SDM system

- Coordination with the system provider

- Method development for SDM data management

- Support and training of employees

Using Systems Engineering Data Management to successfully manage test and simulation data.

Find more information on our SDM services in the PDF flyer

Please download our information brochure on Simulation Data Management below.

FAQ – frequently asked questions about Simulation Data Management

The main difference is in the structure and the amount of data managed. In the PDM system, development data and assembly structures are usually managed from the engineering point of view, i.e. CAD models that are structured into assemblies. In an SDM system, the relevant data for a simulation process, such as simulation models, boundary and load conditions, simulation results and reports, which are required along the simulation process or arise in the simulation process, are managed.

SDM and TDM are related in two ways. On the one hand, more and more tests are being replaced by simulations in order to increase efficiency and speed in product development. In order to be able to fully validate a product, hybrid validation plans must be created that lead partly to simulation results and partly to test results. In this case, simulation results and test results complement each other. On the other hand, there are also validations where test and simulation results have to confirm each other. In this case, simulation results and test results must be compared. In both cases, a close coupling of SDM and TDM systems makes sense. An extension to system modelling and architecture then leads to comprehensive model management within the framework of the aforementioned SE-DM solution concept.

Simulation Data Management systems should primarily reduce the efforts for activities with low added value. These are primarily the efforts for data search, data procurement and the efforts required to document (generate reports) which simulation data have led to which simulation results. SDM systems support and automate these activities, which saves significant time. This freed-up time can be used for activities with greater added value.