What is Model-Based Definition?

Our understanding of Model-Based Definition

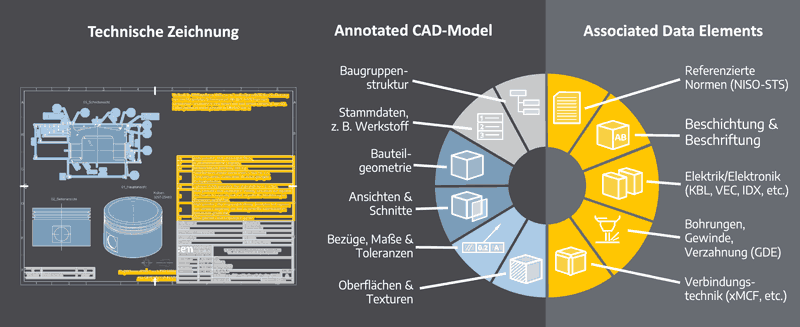

Model Based Definition (MBD for short) stands for a completely digital and model-based approach in the documentation of mechanical and mechatronic products with the help of the so-called 3D Master.

MBD includes the description and documentation of geometric dimensions and tolerances as well as other technical information for production with the help of Product Manufacturing Information (PMI) directly in the 3D CAD model (3D Master). On the other hand, MBD includes the documentation of all non-geometric, technical information for use and provision with the help of the Technical Data Package (TDP) or Digital Data Package (DDP).

What added value does our Model-Based Definition consultancy offer you?

Strategic advice and creation of your individual Model-Based Definition roadmap

Convince decision-makers and inspire users with handy recommendations for action and practical 3D Master demos based on your 2D drawings and 3D CAD models.

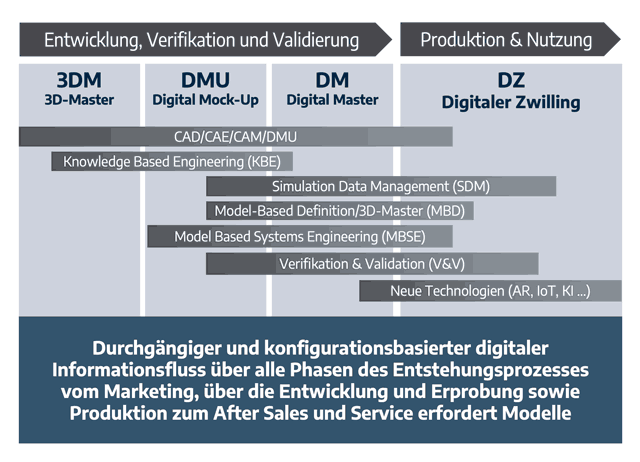

Building Digital Threads for the Model-Based Enterprise and creating digital consistency as a basis for the Digital Twin in your company

More transparency, more speed, fewer errors with Model-Based Definition

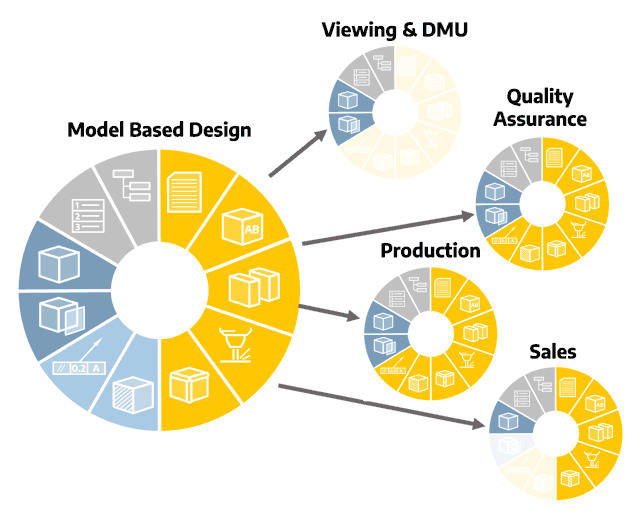

With Model-Based Definition, a completely digital and thus human- and machine-readable product documentation is achieved for the first time. All persons and software tools involved can now access exactly the information that is relevant to them in a targeted manner and without lengthy searches. This saves time, avoids errors and reduces high costs for corrections and changes.

With the help of 3D Master and the Technical Data Package, Model-Based Definition can completely replace the technical drawing and fully integrated, digital processes can be established.

Smooth communication through standards

Today, seamless communication between product development and its downstream processes is supported by a multitude of technical and professional standards.

These include standard formats (such as STEP and JT), data exchange standards (such as MIL-STD 31000, VDA-ZLP and VDA-DDP), technical standards (such as the ISO GPS standard system for Geometric Product Specification) as well as industry-specific standards and company-specific standards.

We show you what is necessary and important in your situation and show you the way to the beneficial introduction of MBD.

No digitalization without Model-Based Definition – this is how we help you implement it:

Identify MBD potentials

Analysis, quantification and evaluation of the MBD potentials for your processes and PLM/MBx architecture. We use the proven scheme of MBD Capability Maturity Levels.

Create a Model Based Design roadmap

Prioritization of identified MBD potentials and MBD roadmap based on benefits and technical dependencies.

Actual-target analysis and fit-gap analysis

Detailed analysis of the downstream processes (actual) and their information requirements for product documentation (target) as well as carrying out a fit-gap analysis.

Definition of suitable CAD data formats and selection of converter and viewer

Determination of suitable 3D CAD and accompanying formats based on your requirements and boundary conditions. Preferably, open and standardized 3D CAD formats (JT and STEP) are used. In addition, manufacturer-neutral benchmarks and the selection of converters and viewers for the selected 3D and companion formats are supported.

Automate and close process gaps with CAD add-on applications.

Reliable and accepted industry standards take time. We know this all too well, because we also work with customers and committees on standards such as JT, STEP and TDP. With CAD add-on applications, we ensure that your digital thread continues even where the standards still have gaps.

Structure and validation of MBD

Development of processes and methods for building and validating Model-Based Definition.

Introduction of Model-Based Definition

Introduction of 3D Master on the basis of your CAD system and Technical Data Package or Digital Data Package as well as training and support for a systematic and successful application for the benefit of your company.

Anark – Technical Product Data Meets Enterprise Collaboration

:em AG is the strategic partner for sales, implementation and support of Anark products in Germany, Austria and Switzerland as well as Anark Marketing Agent for the whole of Europe.

The Anark Product Suite automates the procurement and publication of technical data.

Anark products at a glance

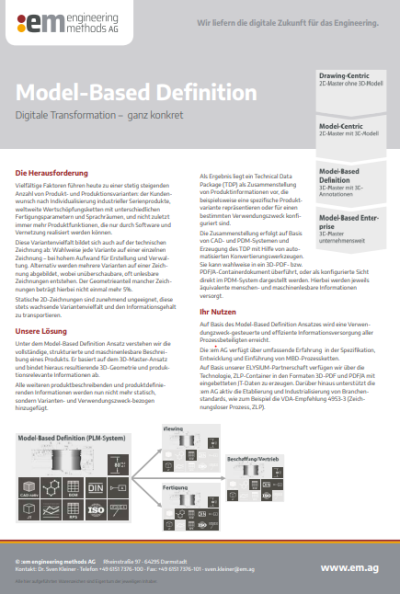

Find more information about our MBD services in the PDF-Flyer

Please download our information brochure on on Model-Based Definition and 3D Master below.

FAQ – frequently asked questions about Model-Based Definition

Model-Based Definition (MBD for short) stands for a completely digital and model-based approach in the documentation of mechanical and mechatronic products with the help of the so-called 3D master.

Model-Based Definition stands for a completely digital and model-based approach in the documentation of mechanical and mechatronic products with the help of the so-called 3D master.MBD includes the description and documentation of geometric dimensions and tolerances as well as other technical information for production with the help of Product Manufacturing Information (PMI) directly in the 3D CAD model – also called 3D Master. On the other hand, MBD includes the documentation of all non-geometric, technical information for use and provision with the help of the Technical Data Package (TDP) or Digital Data Package (DDP).

3D Master is a product design and manufacturing term that refers to a specific method for creating and managing product information. Essentially, 3D master is a strategy for creating a comprehensive digital model of a physical product that contains all the relevant information required for product design, manufacturing and quality control. It is about consolidating all product information into a single 3D CAD model and using this model as the main reference source.

Model-Based Definition (MBD) plays a crucial role in the implementation of the Digital Twin and contributes, for example, to the implementation of the following aspects:

- Digital representation of the system: MBD enables the creation of a digital representation of a physical system, be it a machine, a product, a process or an entire production plant. This digital model forms the basis for the Digital Twin.

- Real-time simulation and analysis: MBD enables the digital model to be used for real-time simulation and analysis of the real system. This means that engineers and manufacturers can test the behaviour of the physical system in a digital environment before it goes into production. This reduces the risk of errors and enables early optimization.

- Continuous improvement: the digital twin can be continuously updated based on real-world data and insights. This allows the physical system to be continuously optimised and adapted to changing conditions or requirements.

- Predictive maintenance: With MBD and the digital twin, companies can develop predictive maintenance methods. By continuously monitoring the digital model and integrating sensor data from the real system, potential problems can be detected early before failures occur.

- Better decision making: MBD provides a better basis for decision-making throughout the life cycle of a product or system. Engineers and managers can access the digital model to make informed decisions regarding design changes, operating parameters, resource allocations and more.

- Reduce costs and time: By using MBD and the Digital Twin, companies can reduce costs and development time. Errors are detected early, changes can be made virtually, and commissioning and validation of the physical system can be more efficient.