Model-Based Systems Engineering (MBSE)

Master product complexity from the system level to the physical level in the domains.

Contact us nowWhat is Model-Based Systems Engineering?

Our definition of Model-Based Systems Engineering

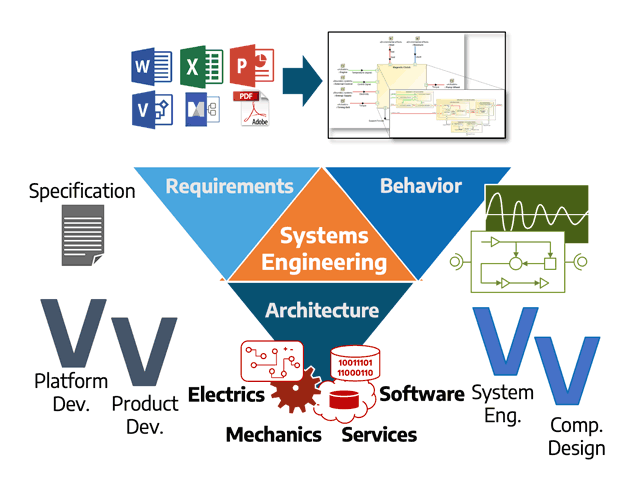

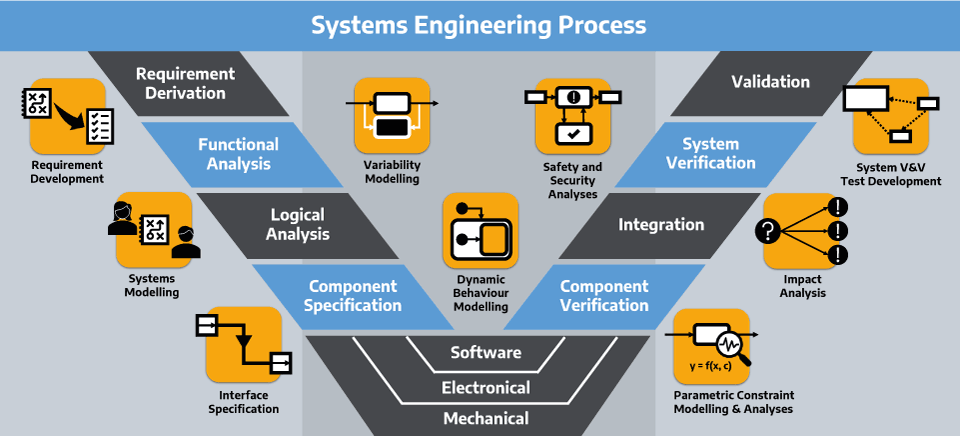

Model-Based Systems Engineering, or MBSE for short, stands for the application of interdisciplinary system development methods in the form of interlinked information models. MBSE aims to manage product complexity by means of consistent modelling of requirements, system architecture and their verification and validation as a framework for successful holistic design in the technical disciplines.

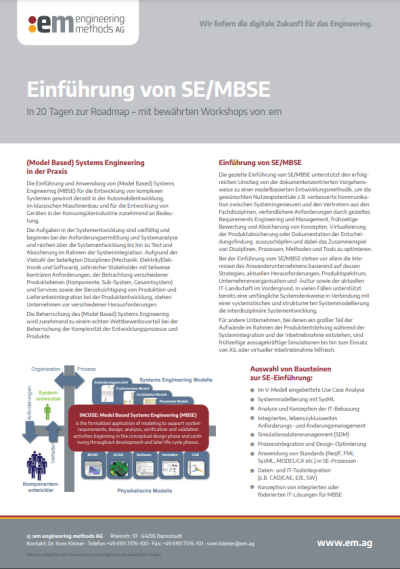

INCOSE: Model-Based Systems Engineering (MBSE)

the formalized application of modeling to support system requirements, design, analysis, verification and validation activities beginning in the conceptual design phase and continuing throughout development and later life cycle phases.

What added value do our services in the area of MBSE offer you?

MBSE lays the foundation for the successful development of purpose-driven digital twins

Tailor-made for implementation without overburdening a running organisation

Modularisation and standardisation for flexible, integrated systems with maximum re-use

Model-Based Systems Engineering – our consulting services

Consulting on MBSE strategy

We support you in the introduction and roll-out of (Model-Based) Systems Engineering and Systems Simulation.

Assistance with the selection of methods and tools

Needs-Based support using methods and tools from our :em (MB)SE framework.

Support for the implementation of MBSE

Support for operational pilots and productive projects through training, coaching and on-the-job training.

Embed MBSE in existing structures

Integration of MBSE into the existing development process and your IT landscape.

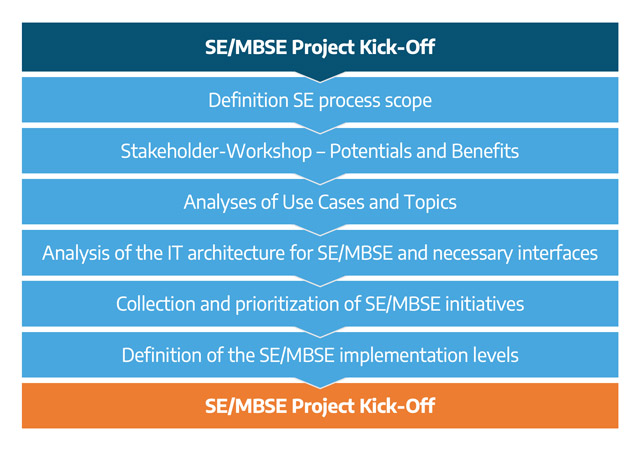

In 20 days to the Model-Based Systems Engineering Roadmap

With our proven SE/MBSE workshop series, we work with you to develop a coordinated and sustainable concept for introducing and establishing (Model-Based) Systems Engineering in your company.

Identify the individual benefits of (Model-Based) Systems Engineering for your organisation and work with us to develop a realistic and customised step-by-step plan with plannable effort and visible added value for each initiative.

Benefit from a common product understanding in your value creation process, even across globally distributed, interdisciplinary teams, through the empowerment of

- early identification of problems

- systematic risk management

- structured development planning

- agile realisation

- modularisation and standardization

- flexibilization of solutions with maximum reusability

- early and continuous verification

- Verifiability of all relevant contexts and decisions

Face complexity sustainably and efficiently – with Model-Based Systems Engineering and us at your side!

Advanced Systems Engineering

Your competitive advantages

- Collaborative work culture and systematic organisation of development leads to improved communication and decision making

- Model-based system development and digital twins increase product quality at an early stage and ensure product maturity at market entry

- Risk analyses, accompanying calculations and simulation serve to safeguard cyber-technical systems and development projects

- Digitalisation reduces time and costs for system and component development

Our services

- (Model-Based) Systems Engineering (MBSE) and System-of-Systems (SoS) Engineering

- Methodology for model-based development of product and production systems

- Benchmark, IT system selection and introduction of MBSE tools

- System Modelling, System Simulation and System Integration

- Product Line Engineering (PLE) and variant/configuration management

- Consulting, training, coaching and support for the introduction and application of MBSE

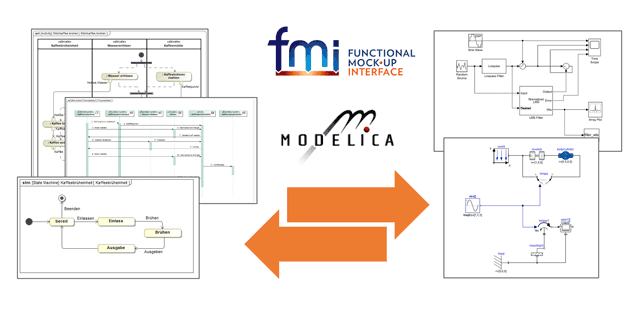

Use of System Simulation in an MBSE-Based development process

System Simulation makes it possible to holistically analyse the behaviour of complex, multi-physical systems. For this purpose, the overall system is decomposed into subsystems whose simulation models are created with the associated interfaces.

In this way, the System Simulation follows principles which are also applied in the decomposition of the system model.

Through combination with Model-Based Systems Engineering, the simulation models can be linked with further information (such as requirements, test cases, system parameters). Due to the resulting continuous traceability between system and simulation model, interrelationships in the overall system can be determined and analysed early on, which would otherwise only become apparent late in the development process.

Holistic product line engineering (PLE) with pure::variants

A dedicated and systematic approach to variant management is essential for effectively addressing the increasing complexity of products, diverse market demands, and unexpected customer requirements.

About pure::variants

Find more information about our MBSE services in our PDF flyers.

Please download our information brochures on MBSE below.

FAQ – frequently asked questions about Model-Based Systems Engineering

MBSE helps to maintain an overview of complex systems, to understand interrelationships and specifications and thus to fulfil all defined requirements.

MBSE thus lays the foundation for the successful development of future innovative products, product lines and cyber-physical systems. The modularisation and standardization of digital product development shortens development cycles, reduces personnel deployment and lowers costs while improving quality.

Through the use of MBSE, more effort is put into the creation of consistent system models in the early phases, as well as their linkage with the resulting requirements, which is more than compensated for by a later, significantly more consistent and stringent realisation due to the significantly higher quality, because more correct, consistent and complete specifications. Ultimately, the use of MBSE saves time and effort, which is reinforced by repeated use in subsequent product generations or variants.

The aim of system simulation is to simulate the interdisciplinary behaviour of systems and subsystems as realistically as possible. The system model, on the other hand, primarily specifies the target behaviour of systems. The combination of both approaches enables a direct analysis and comparison of target and actual behaviour. Care should be taken to ensure that the system model and simulation model are structured as identically as possible so that these analyses can be carried out at different system levels. Simulations can be used in different phases of product development and usually gain in accuracy as development progresses. They can therefore be used both in early phases for system design and in later phases for validation.

MBSE is a broad and comprehensive field that offers methods and tools for the entire product life cycle. For example, the most common language for systems modelling, the “Systems Modelling Language (SysML)”, is designed for a wide range of use cases and should be adapted for the specific needs of a company’s product development. Without a broad understanding of the prerequisites, possibilities and risks of MBSE methods and tools, there is a risk of using them incorrectly and thus missing their purpose and failing to leverage the added values or even incurring additional costs. For these reasons, some companies have so far shied away from the topic, whereas other companies have not been successful in their first pilots due to typical stumbling blocks. Therefore, in addition to knowledge of the strengths and weaknesses of the respective methods and tools, experience and a systematic approach are essential to avoid stumbling blocks and to use MBSE in a targeted and profitable way.